News

2016-04-25

Quality shapes future

April 25 - 28, Booth Number: N1J31

LANXESS at Chinaplas 2016

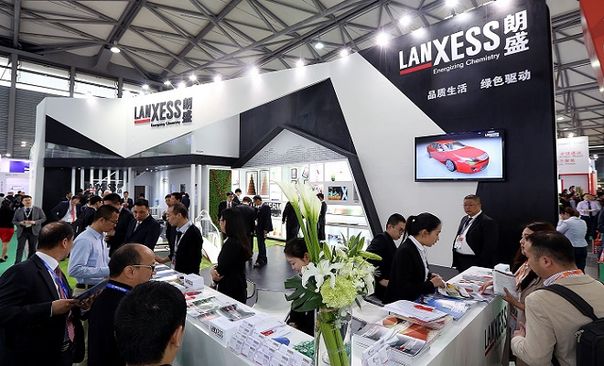

Shanghai – Specialty chemicals company LANXESS will present its comprehensive range of green solutions for the plastics industry at Chinaplas 2016 under the theme of “Green solutions for a quality life.” High-tech plastics, inorganic pigments, colorants, flame retardants and plasticizers from the LANXESS High Performance Materials business unit, Inorganic Pigments business unit and Rhein Chemie Additives business unit facilitate a quality life by bringing added value to the plastics and its downstream industries. The tradeshow will take place at Shanghai New International Expo Center from April 25-28.

“With our broad product portfolio to the plastics industry, we are well positioned to bring higher quality, greater safety and greener solutions to our customers,” said Ming Cheng Chien, CEO of LANXESS Greater China. “Chemicals are indispensable elements not only in the plastics industry but also in our everyday life. With our expertise and experiences in chemistry, LANXESS is committed to improving quality of people’s life.”

Innovative materials for lightweight structure

LANXESS High Performance Materials business unit has established benchmarks in lightweight with polyamide plastic-metal composite technology – also known as hybrid technology. This technology does an excellent job of uniting the weight reduction associated with plastics, and retaining the stability properties of metal. To date, roughly 100 different models of series production vehicles from leading automakers are using this technology.

With its Tepex® continuous fiber-reinforced thermoplastic composites, LANXESS pushes the boundaries where the composite and high-tech plastics can be used in place of metals. Despite its very low weight, Tepex® combines impressive stiffness with outstanding strength. Moreover, benefiting from short cycle times and very reproducible processes, it can be turned into three-dimensional components with great cost-efficiency. In many cases, Tepex® is a high-performance and cost-effective alternative to carbon fiber-reinforced thermoset lightweight materials.

LANXESS will showcase a seat pan at the show which is significantly lighter compared to a steel version while fulfilling all necessary crash and mechanical requirements. It is made out of Tepex® dynalite 102 RG600(2)/47% and the impact modified polyamide 6 Durethan® DP BKV 240 H2.0.

The seat pans owe their high stability in the event of a crash to the endless fiber reinforcement in the semi-finished composite sheets. This leads to a very high strength of the part. Furthermore, the Tepex® composite sheet stands out with a very good formability.

Produced through fully automatic, economical one-shot process, the seat pans are provided by the injection molding process with numerous functional integrations such as connections to the seat heating and adjustment electronics or the mounting to the seat structure.

“Such an example of a complex safety relevant application shows that it is possible to combine the great weight saving potential of thermoplastic composites with an economical serial production process,” said Milan Vignjevic, Head of Sales & Marketing for High Performance Materials business unit for Asia Pacific.

Besides seating applications, LANXESS is expecting big potential for Tepex® dynalite in other applications like frontends, pedals, components for automobile doors and hatches, arm rests, underfloor covers and carriers for electronic components.

With its expertise in cost efficient lightweight design and wide range of thermoplastic compounds and composite sheets marketed under the brand names Durethan®, Pocan®, and Tepex®, LANXESS is helping the automotive industry to increase fuel efficiency and to reduce emissions for sustainable mobility.

New Red Iron Oxide Pigments produced with patented Ningbo Process

The Inorganic Pigments business unit will present a wide color range for different plastics applications including red, yellow, black, and brown iron oxide pigments as well as green chromium oxide pigments marketed under the brands Bayferrox® and Colortherm®. A special highlight for this year’s Chinaplas will be the introduction of the New Red shades which are manufactured in the new LANXESS production plant in Ningbo. They will be marketed globally under the trusted Bayferrox® brand name and represent a further expansion of the product portfolio of the world's largest iron oxide producer.

“As the leading producer of iron oxide pigments, we continuously strive to improve even the best portfolio – for example by conquering a new color space of bright red shades for our customers worldwide. In Ningbo, we not only built a new production plant for red pigments, but we also developed a whole new production process for our highly saturated New Red pigments: the Ningbo Process. It stands out due to its improved efficiency for our customers and, at the same time, sets a new benchmark of sustainability on a global scale,” said Rafael Suchan, Vice President for the Inorganic Pigments business unit for Asia Pacific. “With our New Red pigments from Ningbo we will further strengthen our leading position in the Chinese as well as in the global market.

Special pigments for the coloring of plastics

China is the world’s single largest plastics manufacturing and consuming market. LANXESS offers a broad range of inorganic color pigments satisfying highest requirements in plastic applications.

Artificial turf, for example, needs proper coloration if it is to be virtually indistinguishable in appearance from its natural counterpart. Colortherm® pigments often serve as coloring components for artificial turf. In particular, Colortherm® Yellow 20 is widely used for the coloration and UV protection of artificial turf fibers, in combination with an organic blue pigment. Colortherm® iron oxide pigments are not only cost-effective, they are also very lightfast and resistant to weathering, with no decrease in color intensity over the lifespan of the turf.

Colortherm® inorganic pigments also have been proven effective in coloring wood plastic composites and provide more color choices for these composites such as Colortherm® Yellow 3950 and Colortherm® Green GN. These products exhibit good dispersibility, even in processes which have short dwell times and relatively low shear forces. They are easy to break down and distribute to reach its final tinting strength quickly. Other advantages include their lightfastness and weather-resistance.

Additives for greater safety and better performance

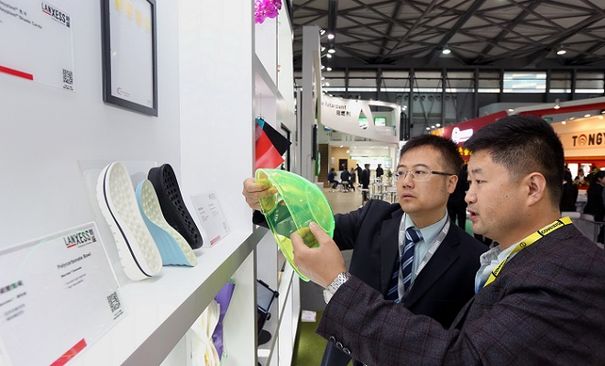

The LANXESS Rhein Chemie Additives business unit offers a broad range of high-quality additives, phosphorus chemicals, specialty chemicals and colorants that improve the processability of plastics and give the finished articles the desired properties.

For many years LANXESS has concentrated on providing products and solutions that help its customers address constantly increasing regulatory requirements. The plasticizers portfolio led by its flagship product Mesamoll® is already entirely phthalate-free, and helps users in the PVC, rubber and PU adhesives and sealants industries to react to increasing requirements on the regulatory side.

Mesamoll® is compatible with many types of polymers including PVC and polyurethanes. It features lower processing temperatures and shorter cycle times than many other plasticizers. Manufacturers are seeking out Mesamoll® not just for its safe, phthalate-free formulation, but also for its very good plasticizing capacity. Besides, its high saponification resistance is especially beneficial for articles that come into contact with water and alkalis. The approvals granted for food contact applications are another advantage.

Macrolex® dyes are soluble dyes in various colors enabling brilliant formulations in plastic. Macrolex® dyes meet numerous legal conditions for use in food packaging and toys. They make it possible to achieve excellent results in coloring amorphous polymers such as PS, PC, ABS, PMMA and PET. Coloration can range from transparent to full coverage, depending on the polymer and combination of colorants. Other benefits are high color intensity, outstanding brilliance, very good weather resistance and lightfastness and excellent heat stability.

Disflamoll® and Levagard® phosphorus-based, non-halogenated flame retardants are suitable for making flame-retardant polyurethane foams and resins, thermosets and flexible PVC.

Rhein Chemie Additives hydrolysis stabilizers from the Stabaxol® product range are well established in their core end markets of PET monofilaments, polyamide, polyester polyurethane and TPUs. Using Stabaxol® brings an up to threefold increase in the stabilized polymer's lifespan. This extended lifespan means that it is possible to use reasonably priced polymers in applications that would otherwise require the use of very high-quality and substantially costlier plastics such as PPS or PEN. Plastics stabilized with Stabaxol® have a very good cost-benefit ratio.

“Outstanding product quality, long-established technical expertise and the satisfaction of a wide range of essential regulatory requirements – these are the defining features of our product portfolio,” said Hak Leong Chok, Sales Vice President, Rhein Chemie Additives business unit for Greater China, ASEAN and ANZ region.

Chinaplas is Asia’s largest plastics and rubber trade fair. This year, the theme of the trade show is “Greenovation for a Smart Future.”

“Together with our customers, we are working hard to build a better future for our society via new technologies, innovative products, and sustainable solutions,” concluded Chien.

About LANXESS

LANXESS is a leading specialty chemicals company with sales of EUR 7.9 billion in 2015 and about 16,200 employees in 29 countries. The company is currently represented at 52 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of chemical intermediates, specialty chemicals and plastics. Through ARLANXEO, the joint venture with Saudi Aramco, LANXESS is also a leading supplier of synthetic rubber. LANXESS is listed in the leading sustainability indices Dow Jones Sustainability Index (DJSI World) and FTSE4Good.

LANXESS China

On Jan. 31, 2005, LANXESS AG was initially listed on the Frankfurt Stock Exchange, and its subsidiary LANXESS Chemical (China) Co., Ltd. officially began operations. Today, LANXESS has 10 subsidiaries including two joint ventures, as well as eight R&D centers in China, with about 1,500 employees in Greater China. LANXESS works closely with its local partners to develop market-oriented solutions that meet local market needs.

Forward-Looking Statements

This news release may contain forward-looking statements based on current assumptions and forecasts made by LANXESS AG management. Various known and unknown risks, uncertainties and other factors could lead to material differences between the actual future results, financial situation, development or performance of the company and the estimates given here. The company assumes no liability whatsoever to update these forward-looking statements or to conform them to future events or developments.

Information for editors:

All LANXESS news releases and accompanying photo, video and audio materials can be found at www.lanxess.cn, www.weibo.com/lanxess, or LANXESS’ official WeChat account: LANXESS_china